Robotics for heavy industries

Game-changing benefits

This is a game-changing robotic solution within heavy industry bringing Ventherm A/S’ clients up to the next level.

- High flexibility and surface quality.

- Increased production capacity by ensuring a constant and smooth workflow.

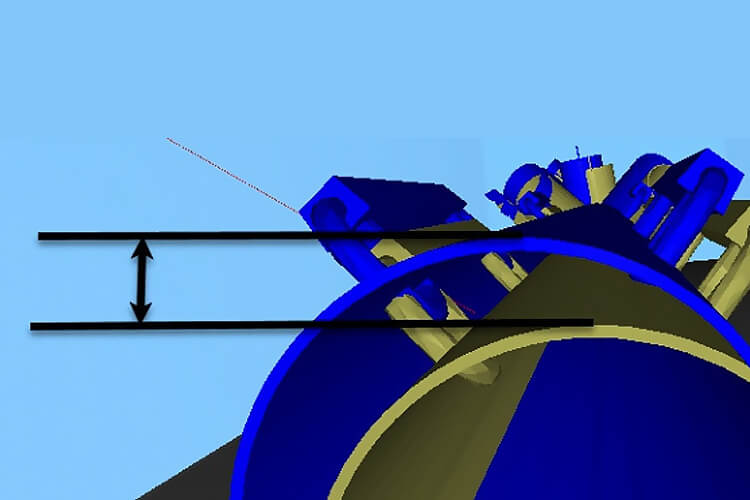

- Optimal paint paths.

Reduce and control paint consumption. - No human robot programming.

- Reduced costs for personnel.

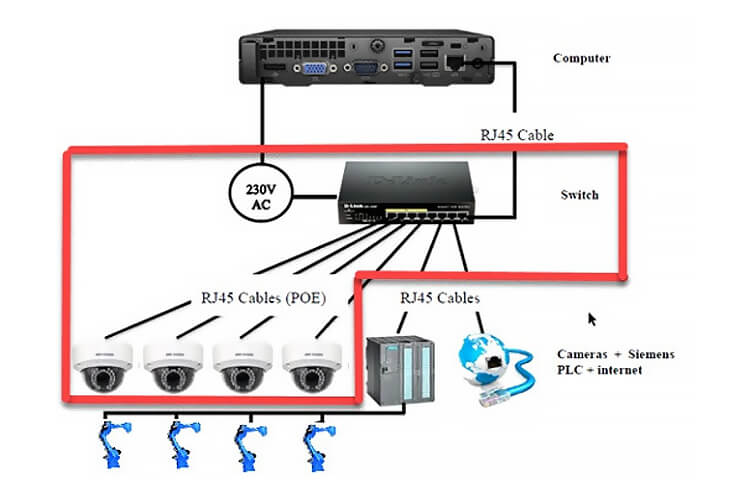

- Controlled by app or PC.

- Reliable software developed in Denmark.